Inspection reports give you the upper hand in supplier negotiation. When you use a trusted third-party inspection service in China, you gain a reliable set of eyes and a dedicated quality guardian on the ground. Objective inspection data helps you address quality concerns with facts, not opinions. You can confidently negotiate for better pricing, improved terms, or corrective action. With clear evidence in hand, you protect your interests and ensure your suppliers deliver what you expect.

Key Takeaways

- Inspection reports provide objective data on product quality, helping you negotiate confidently with suppliers.

- Use clear defect rates and compliance findings from inspection reports to support requests for rework, replacements, or price adjustments.

- Prepare thoroughly by reviewing inspection data and comparing it with market standards to set realistic negotiation goals.

- Present findings in a clear, factual manner to build trust and transparency with suppliers during negotiations.

- Regular inspections and well-documented communication strengthen supplier relationships and ensure accountability.

Inspection Reports in Supplier Negotiation

What Are Inspection Reports?

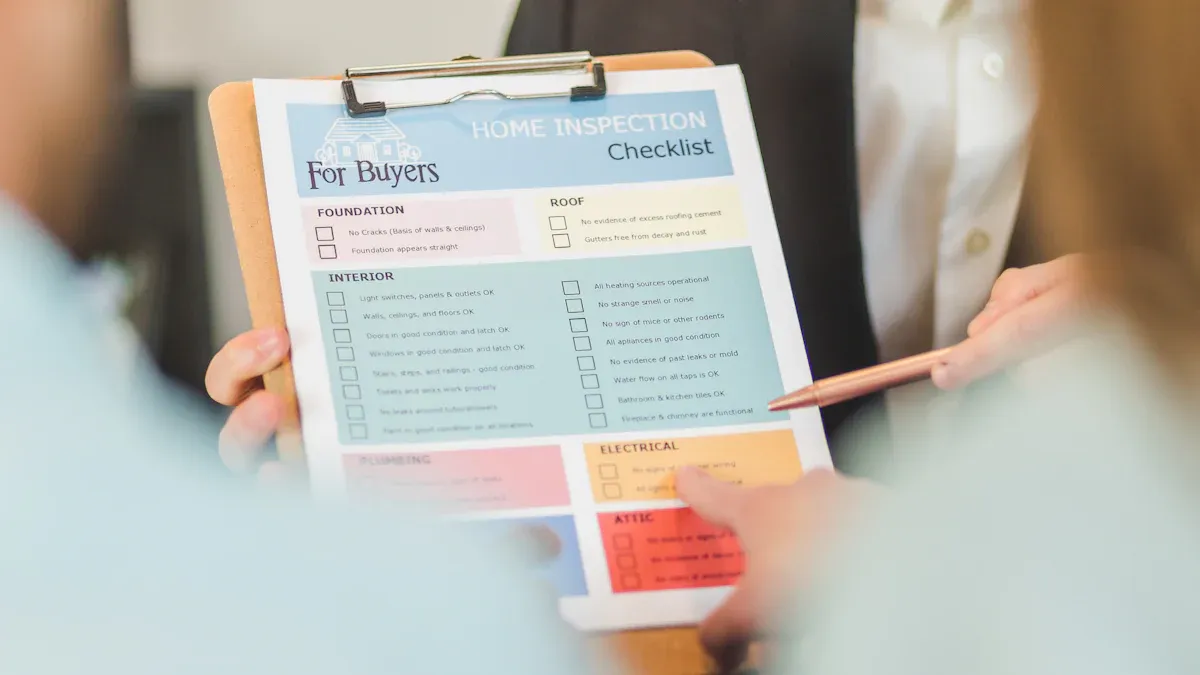

Inspection reports serve as your objective record of product quality, quantity, and condition before shipment. These documents detail the results of thorough checks performed by third-party professionals. You receive clear evidence about whether your goods meet agreed-upon specifications and quality standards.

A pre-shipment inspection report is a crucial document that verifies the quality, quantity, and condition of goods before they are shipped to the buyer. This report assures that the products you’re about to send meet the agreed-upon specifications and standards.

When you use inspection reports, you gain a reliable foundation for supplier negotiation. You can reference specific findings, such as defect rates or packaging issues, to support your requests for better terms or corrective actions.

Why They Matter

Inspection reports play a vital role in supplier negotiations. You move beyond subjective opinions and rely on facts. Third-party inspection services, such as Testcoo, act as your quality control partners in China. Their expertise and independence ensure that the data you present is trustworthy and unbiased.

Here’s how third-party inspection services like Testcoo strengthen your negotiation position:

| Evidence Description — | Contribution to Supplier Negotiation — | | Inline inspections catch defects early, allowing corrections before mass production. — | This proactive approach enhances negotiation leverage by ensuring timely delivery and quality compliance. — | | Conducting inspections during production helps catch defects early, saving time and money. — | This minimizes risks and strengthens the brand’s position in negotiations. — | | Testcoo offers flexible scheduling and same-day reports, supporting faster supply chains. — | This efficiency builds trust with suppliers, improving negotiation outcomes. — |

You gain leverage and transparency when you present inspection reports. Suppliers see that you base your decisions on objective data. This approach encourages accountability and fosters a more professional relationship. You can negotiate with confidence, knowing that your requests are backed by documented evidence.

Key Report Elements

Inspection reports contain several critical data points that shape your supplier negotiations. You rely on these elements to assess product quality and drive meaningful discussions with suppliers. Each inspection scenario—sample inspection, pre-shipment inspection, and container loading supervision—offers unique insights.

Defect Rates

Defect rates reveal the percentage of products that fail to meet your standards. You use this information to measure product quality across batches. High defect rates signal problems in manufacturing or quality control. During sample inspection, you compare defect rates from different suppliers to select the best option. In pre-shipment inspection, you identify issues before authorizing payment or shipment. Container loading supervision helps you confirm that only acceptable goods leave the factory.

Tip: Presenting clear defect rates gives you strong leverage when negotiating for rework, replacements, or price adjustments.

Compliance Issues

Compliance issues highlight whether products meet regulatory and contractual requirements. You check for safety hazards, labeling errors, and adherence to industry standards. Consistent compliance ensures product quality and protects your brand reputation. Inspection reports document compliance findings, making it easier for you to address concerns with suppliers.

| Type of Issue | Examples |

|---|---|

| Safety Issues | Electrical hazards, structural concerns, mold |

| Structural Problems | Foundation issues, water intrusion, roof defects |

| Systems Failures | HVAC, plumbing, or electrical systems nearing end of life |

| Superficial Concerns | Cosmetic issues, minor wear and tear |

You use compliance data from sample inspections to screen new suppliers. Pre-shipment inspections confirm that bulk orders meet your requirements. Container loading supervision verifies that all goods shipped comply with your expectations.

Packaging & Delivery Findings

Packaging and delivery findings affect product quality during transit. You review packaging integrity, labeling accuracy, and shipment conditions. Poor packaging can lead to damaged goods and customer complaints. Inspection reports detail packaging flaws and delivery risks, helping you negotiate for improved packing methods or additional safeguards.

Note: Addressing packaging and delivery findings early prevents costly returns and strengthens your supply chain reliability.

You gain a comprehensive view of product quality by analyzing defect rates, compliance issues, and packaging findings. These elements empower you to negotiate confidently and secure better outcomes with your suppliers.

Supplier Negotiation Strategies

Preparing with Inspection Data

Preparation forms the backbone of successful supplier negotiation. You start by gathering all relevant inspection reports and reviewing the findings in detail. Focus on the most recent sample inspection, pre-shipment inspection, or container loading supervision results. Identify key issues such as defect rates, compliance problems, or packaging concerns. This approach gives you a clear picture of the product’s strengths and weaknesses.

Before entering supplier negotiations, compare your inspection data with market standards and competitor offers. This research boosts your confidence and helps you set realistic goals for better pricing or improved terms. Organize your documentation so you can quickly reference specific findings during discussions. When you prepare thoroughly, you enter the negotiation with a strong foundation and clear objectives.

Tip: Regular inspections and up-to-date reports help you spot trends and recurring issues, making your negotiation strategy more effective.

Presenting Findings

Presenting inspection findings in a clear, objective manner sets the tone for a productive supplier negotiation. Use concrete data from your reports to support your requests. Avoid emotional language and focus on facts. This approach encourages transparency and builds trust with your supplier.

- Data-driven discussions provide a solid foundation for negotiation.

- Both you and your supplier understand the rationale behind each proposal.

- Transparency leads to a more practical and less emotional negotiation process.

Show your supplier the specific areas where products did not meet expectations. Use photos, defect rates, and compliance notes from your inspection reports. This method demonstrates that your requests for better pricing or corrective action are based on evidence, not opinion.

Note: When you present findings objectively, you foster a professional relationship and reduce the risk of misunderstandings.

Framing Requests

Framing your requests effectively is essential for achieving your negotiation goals. Start by stating your expectations clearly, referencing the inspection data as your basis. For example, if the defect rate exceeds your acceptable limit, request rework, replacement, or better pricing. If packaging does not meet your standards, ask for improvements before the next shipment.

Follow these actionable negotiation strategies to maximize your results:

- Conduct thorough research on market prices and competitor offers to gain confidence in supplier negotiations.

- Focus on building strong relationships with suppliers to foster trust and flexibility.

- Start with small orders to establish trust before negotiating larger quantities.

- Look beyond just price; consider other value-added aspects like shipping and production speed.

- Maintain professionalism and clear communication to strengthen relationships.

- Be prepared to walk away if terms are not favorable.

Clear documentation and communication play a vital role in successful supplier negotiations. When you document agreements, you prevent misunderstandings and create accountability for both parties. Specify roles, timelines, and conditions to ensure smooth implementation. Define the scope of work and deliverables, establish key performance indicators, and set transparent payment terms. This clarity reduces the likelihood of disputes and helps both sides achieve their goals.

Remember: Consistent, well-documented communication and regular inspections keep your supplier accountable and support long-term success in supplier negotiation.

Using Inspection Reports in Supplier Negotiations

Price Reductions

You can use inspection reports to negotiate price reductions with your suppliers. When you identify significant defects or compliance issues, you gain leverage in the negotiation process. Focus on major problems that impact product quality or usability. Avoid spending time on minor repairs that do not affect the overall value of the shipment.

- Review the inspection report for substantial defects.

- Present repair estimates to support your request for lower pricing.

- Maintain a professional attitude during discussions.

For example, if the inspection report highlights electrical issues or structural problems, you can request a reduction in pricing to offset the cost of repairs. Suppliers often respond positively when you provide clear documentation and reasonable estimates. You demonstrate your commitment to fairness and transparency, which strengthens your position.

Tip: Always base your pricing requests on objective data from the inspection report. This approach shows you are focused on facts, not opinions.

Rework or Replacement

Inspection reports help you negotiate for rework or replacement of defective goods. When you discover products that do not meet your standards, you can request the supplier to correct the issues before shipment. Use the report to specify which items require attention and outline the necessary steps for improvement.

- Identify defective items using the inspection report.

- Communicate your expectations for rework or replacement.

- Set clear deadlines for corrective actions.

You add value to your negotiation by providing detailed feedback and actionable solutions. Suppliers appreciate clear instructions and measurable goals. This process reduces misunderstandings and ensures you receive products that meet your requirements.

Note: Early inspections allow you to address problems before final shipment, saving time and reducing costs.

Improved Terms

Inspection findings often lead to negotiations for improved terms. You can request better payment schedules, enhanced packaging, or additional quality checks based on the report’s results. Suppliers are usually willing to address major concerns, such as structural defects or system failures, to maintain a positive relationship.

Common issues that prompt negotiations include electrical problems, plumbing failures, and HVAC system concerns. Sellers typically resolve these major defects, while buyers negotiate for monetary compensation for less critical issues. This arrangement gives you flexibility and control over how you address minor problems.

You can also use inspection data to negotiate long-term contracts that stabilize pricing and ensure consistent quality. Suppliers value clear communication and structured agreements. You build trust and accountability by setting measurable standards and regular inspection schedules.

| Challenge | Solution |

|---|---|

| Tracking Supplier Performance | Establish clear metrics and use SRM software for monitoring. |

| Poor Product Quality | Set measurable quality standards and conduct regular inspections. |

| Delayed Deliveries | Communicate delivery expectations and use supply chain management tools. |

| Communication Breakdown | Set up structured channels and regular meetings. |

| Pricing Fluctuations | Negotiate long-term contracts to lock in pricing. |

Tip: Improved terms add value to your supply chain and protect your interests over time.

Sample Scripts

You can use sample negotiation scripts to guide your discussions with suppliers. These scripts help you present inspection findings clearly and request specific actions. Building rapport and trust is essential for successful negotiations.

Sample Script for Price Reduction:

Hello [Supplier Name],

Thank you for providing the inspection report. I noticed several significant defects, including [list major issues]. Based on the repair estimates, I would like to discuss a reduction in pricing for this shipment. Please let me know your thoughts so we can reach a fair agreement.

Best regards,

[Your Name]

Sample Script for Rework or Replacement:

Hi [Supplier Name],

The inspection report identified some items that do not meet our quality standards, such as [list defects]. I request that these products be reworked or replaced before shipment. Please confirm the timeline for these corrections.

Thank you,

[Your Name]

Sample Script for Improved Terms:

Dear [Supplier Name],

After reviewing the inspection report, I believe we should adjust our agreement to include [improved packaging, additional inspections, or better payment terms]. These changes will add value to our partnership and ensure consistent quality. Please let me know if you agree with these adjustments.

Sincerely,

[Your Name]

Handling disputes or supplier pushback requires a strategic approach. You can use objective inspection data to resolve disagreements and maintain a positive relationship.

- Build a strong supplier relationship by treating your supplier as a partner.

- Train suppliers on inspection standards to minimize misunderstandings.

- Address issues early in the production cycle to allow for corrections.

- Use data to identify and solve root causes collaboratively.

You overcome challenges by establishing clear quality standards, communicating expectations, and negotiating long-term contracts to stabilize pricing. Regular inspections and structured communication channels add value and ensure supplier accountability.

Note: A notable case involved a supplier facing severe consequences due to poor quality control. The FDA recalled their onions linked to an E. coli outbreak, resulting in multiple infections and lawsuits. This incident highlights the importance of regular inspections and clear performance metrics.

| Challenge | Solution |

|---|---|

| Poor Product Quality | Establish clear quality standards and conduct regular inspections. |

| Delayed Deliveries | Clearly communicate delivery expectations and monitor progress regularly. |

| Communication Breakdown | Implement structured communication channels and regular updates. |

| Pricing Fluctuations | Negotiate long-term contracts to stabilize pricing. |

Tip: Use inspection reports as your foundation for every negotiation. You protect your interests, add value to your supply chain, and secure favorable pricing and terms.

Maximizing Impact

Documentation Best Practices

You strengthen supplier relationships by keeping thorough records during every inspection period. Document each inspection report, contract amendment, and home inspection finding. Use clear checklists and templates to track supplier performance. Store photos, videos, and diagrams from inspections to clarify issues. Highlight important parts of images with arrows or colors. Modern software helps you create visually engaging reports. Share these documents instantly with all stakeholders. Well-organized documentation supports relationship management and helps you resolve disputes quickly. You build trust by maintaining transparency in every contract and inspection period.

Communication Tips

Effective communication drives successful supplier relationships. You should collaborate with suppliers to improve the inspection process. Understand their production methods and quality checks. Maintain open communication to align expectations. Use pictures, videos, and diagrams to clarify findings from each inspection period. Provide regular feedback and updates to suppliers. Issue alerts for serious discrepancies in inspection reports. Share detailed reports with all relevant parties. Open dialogue helps you negotiate long-term contracts and manage relationship challenges. Strong communication ensures timely deliveries and supports supply chain efficiency.

Maintaining clear and consistent communication throughout the inspection period is essential. Before each home inspection or audit, make sure suppliers understand the objectives and scope. During the inspection, promptly communicate any non-conformances and set clear expectations for corrective actions.

Follow-Up Actions

After supplier negotiations, you need to monitor progress and maintain accountability. Establish regular communication to track corrective actions and resolve issues. Develop a corrective action plan with suppliers, detailing tasks, responsibilities, timelines, and KPIs. Prioritize critical issues first, considering the supplier’s capacity. Conduct follow-up audits if progress is insufficient. Document all monitoring activities to ensure transparency and support future decisions. Regular audits, both on-site and remote, ensure suppliers adhere to compliance standards. Findings from each inspection period lead to corrective actions, which you track and assess in follow-up audits. This process fosters ongoing supplier accountability and strengthens supplier relationships.

| Benefit of Regular Audits — | Impact on Supplier Relationships — |

|---|---|

| Enhanced transparency — | Builds trust and improves relationship management — |

| Cost reductions — | Minimizes defects and rework — |

| Improved product reliability — | Boosts customer satisfaction — |

| Stronger supplier relationships — | Contributes to supply chain resilience — |

You can negotiate a price reduction in lieu of repairs when inspection reports reveal major defects. Long-term contracts and regular inspections help you maintain high standards and reliable supplier relationships. Consistent follow-up actions ensure suppliers deliver quality products and meet contract requirements during every inspection period and home inspection.

Inspection reports give you the confidence to negotiate with suppliers using clear facts. When you use third-party inspection services, you gain objectivity, expertise, and leverage:

| Benefit | Description |

|---|---|

| Objectivity | Third-party inspectors provide unbiased reports, free from factory pressure. |

| Expertise | Professional inspectors are trained in quality control best practices and know what to look for. |

| Leverage | If inspections fail, companies can demand rework or replacement before final payment is made. |

You can see real results:

- A buyer in Phoenix secured a $12,000 credit after finding HVAC and plumbing issues.

- In Boston, a couple negotiated $8,000 in repairs and a $3,000 credit.

- An Atlanta investor avoided a costly mistake by walking away from a bad deal.

Start using inspection data and third-party services in your next negotiation. You will protect your interests and achieve better outcomes.

FAQ

What is the main benefit of using inspection reports in supplier negotiations?

You gain clear evidence of product quality. This data helps you negotiate for better terms and ensures suppliers meet your standards. Inspection reports support mutually beneficial agreements and protect your interests.

How do inspection reports help maintain long-term partnerships?

You show suppliers that you value quality and transparency. Regular inspections build trust and encourage long-term partnerships. This approach creates value for both parties and supports ongoing collaboration.

Can inspection reports support negotiating for repairs or replacements?

Yes. When you find defects, you can use inspection data for negotiating for repairs or replacements. This process ensures you receive products that meet your quality expectations before shipment.

How often should you request inspections to ensure consistent quality?

You should schedule inspections at key stages: sample review, pre-shipment, and container loading. Regular checks help you maintain high quality and catch issues early. This routine supports long-term value in your supply chain.

Do inspection reports only focus on product defects?

No. Inspection reports cover all aspects of quality, including compliance, packaging, and delivery. You receive a complete view of your order’s condition, which helps you make informed decisions and secure the best outcomes.