Measuring the cost of quality control helps your business grow. You see how each cost changes your work and profit. Many companies ignore the cost of quality and lose money they do not see. If you watch the cost of quality control, you find problems early and stop big mistakes. The table below shows how knowing these costs helps your business do better:

| Evidence Description | Impact on Business Profitability and Risk Reduction |

|---|---|

| Tracking cost of quality control finds hidden costs. | You make more profit and stop waste. |

| Early failure detection through quality control. | You avoid rule problems and keep your good name. |

| Reducing external failure costs boosts customer loyalty. | You get success for a long time and customers trust you. |

When you know why cost of quality matters, you see quality control as a smart choice. This way of thinking helps you build a strong business that cares about quality all the time.

- Watching the cost of quality control helps you guess risks.

- Using resources better with cost of quality control makes more profit.

- Good quality control makes customers trust you and stay loyal.

Key Takeaways

- Measuring the cost of quality control shows hidden costs. This helps companies make more money and waste less.

- Spending money on prevention and appraisal costs stops bigger problems. This keeps things running smoothly.

- Good quality control makes customers happy. Happy customers come back and help your business grow.

- Checking quality costs often helps companies find ways to get better. This cuts down on waste and makes products better.

- Building a culture of quality in your team helps everyone work together. This leads to better results and saves money.

Cost of Quality Control

Why It Matters

You should know the cost of quality control. It helps your company plan for the future. Tracking these costs shows where your money goes. You learn how each step in your process changes your results. Cost of quality analysis helps you spot hidden problems early. This stops small issues from becoming big ones. You can look at the main parts that make up the cost of quality in both manufacturing and service jobs:

| Component | Description |

|---|---|

| Prevention Costs | Costs related to activities aimed at preventing defects in products or services. |

| Appraisal Costs | Costs incurred to determine if products or services meet quality standards. |

| Internal Failure Costs | Costs incurred when defects are found before the product or service is delivered to the customer. |

| External Failure Costs | Costs that arise when defects are found after the product has been delivered to the customer. |

When you pay attention to these areas, you can lower poor quality costs. You avoid big mistakes and keep your business working well. Cost of quality analysis shows you where to spend your money for the best results. You do not just spend money; you make smart choices that keep your company safe.

Impact on Profitability

Cost of quality analysis shows how much money you save by finding problems early. If you spend on quality, you lower the cost of poor quality like rework, scrap, and returns. These costs can take away your profits and slow your business. Here is how quality control helps your profits:

| Evidence Type | Description |

|---|---|

| Cost Reduction | Effective quality control reduces production costs by catching defects early when correction costs remain minimal. |

| Avoidance of Expenses | Companies avoid expensive rework, scrap, and warranty claims by implementing proper quality control measures. |

| Quantifiable Savings | Statistical analysis shows that quality control can reduce scrap levels, lower labor costs from rework, and improve supply chain accuracy by reducing material waste. |

- A Forrester study found that better defect tracking and early issue detection with TestRail saved 21,700 hours of rework over three years.

- This saved $381,000 in costs.

- Companies using TestRail also saved $1.2 million in test administration and cut software developer inefficiencies by $523,000.

The analysis shows that poor quality control can cost manufacturers a lot of money. This happens mostly through scrap, rework, and returns. These costs hurt your business and can cause other problems that lower profits over time. For example, a small machine part that is not lined up right can cause mistakes in production. This means more rework and returned items. It can slow down work, stop machines, and lower how much you can make. This shows the hidden costs of bad quality control.

You can measure the return on investment from quality control by using financial numbers, getting feedback, and comparing your results to others in your industry. When you track better production and lower unit costs, you see the real value of your quality work. Cost of quality analysis helps you make choices that grow your profits and keep your business strong.

Customer Satisfaction

You want customers to trust what you sell. Cost of quality analysis helps you meet their needs every time. When you spend on quality, you lower poor quality costs and avoid problems that can hurt your name. Research shows that good quality control gives customers better products and services. This makes them happier and more loyal.

Making customer experience better with quality assurance raises satisfaction and builds a strong brand. When you focus on service and delivery, you make customers happy and keep them coming back. Cost of quality analysis lets you see how your work leads to happy customers and long-term success.

Tip: Happy customers will tell others about your business. When you keep quality high and costs low, you build loyal customers who help your business grow.

Cost of Quality Breakdown

Prevention Costs

Spending money on prevention costs helps stop future problems. These costs help you catch defects before they start. When you focus on prevention, your company gets stronger. Prevention costs include things like training, fixing processes, and keeping machines working. These steps help you avoid bigger costs later.

| Cost Category | Description | Examples |

|---|---|---|

| Prevention Costs | Money spent to stop defects before they happen. | Training sessions, preventive maintenance |

| Cost of Good Quality | Money used for things that prevent defects. | Training, process improvement, inspections |

| Cost of Poor Quality | Money lost from mistakes, fixing errors, and unhappy customers. | Scrap, recalls, unhappy customers |

- You can see the value of prevention by checking what you spend on training and changes.

- When you spend on prevention, you get fewer defects and better results.

- Being proactive with quality helps your company do its best.

Tip: Prevention costs might look high at first, but they save you more money later by stopping problems and keeping quality high.

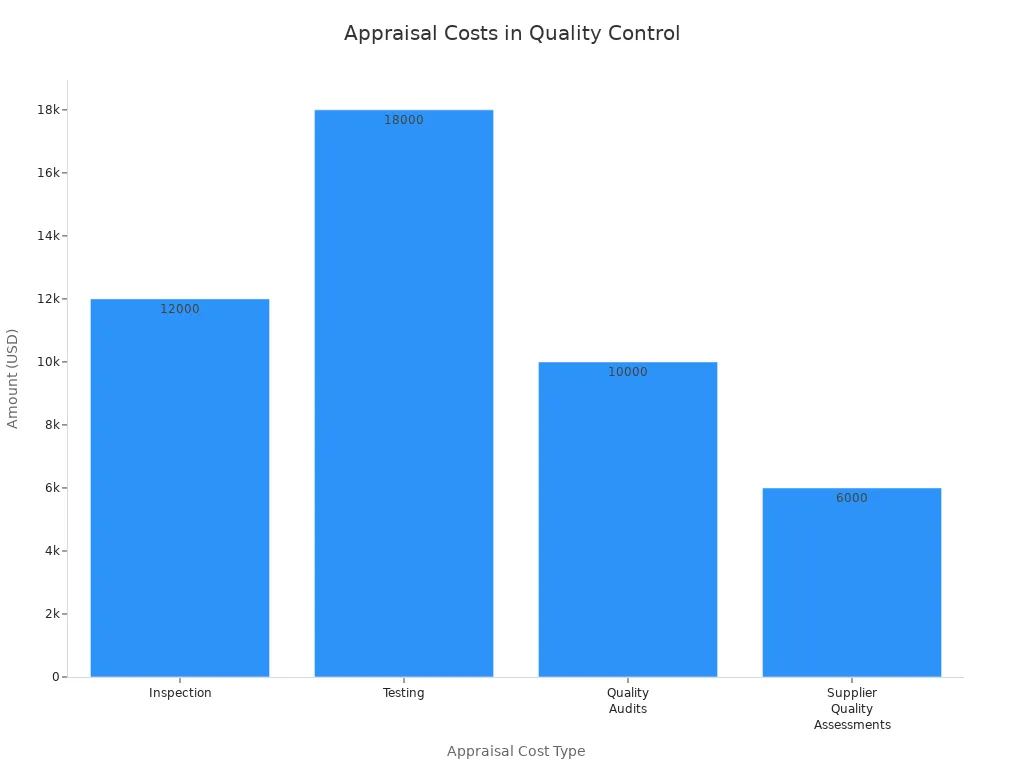

Appraisal Costs

Appraisal costs are what you pay to check if your products or services are good enough. You spend money on things like inspections, tests, audits, and checking your suppliers. These steps help you find problems early and stop bad products from reaching customers.

| Appraisal Cost Type | Amount |

|---|---|

| Inspection | 12,000 |

| Testing | 18,000 |

| Quality Audits | 10,000 |

| Supplier Quality Assessments | 6,000 |

Appraisal costs are important for your quality system. By finding problems early, you avoid bigger costs later. You also keep your company’s good name by making sure only good products go to customers.

Internal Failure Costs

Internal failure costs happen when you find problems before your product leaves your company. These costs include fixing mistakes, throwing away bad products, machine breakdowns, and surprise repairs. All these things waste money and lower your quality.

| Internal Failure | Description |

|---|---|

| Rework | Fixing mistakes or defects during production. |

| Scrap | Throwing away materials or products that have defects. |

| Equipment Downtime | Machines breaking down and stopping work. |

| Unplanned Maintenance | Repairs that happen without warning during production. |

You can lower internal failure costs by making your quality better and teaching your team. Acting quickly stops small problems from getting worse.

External Failure Costs

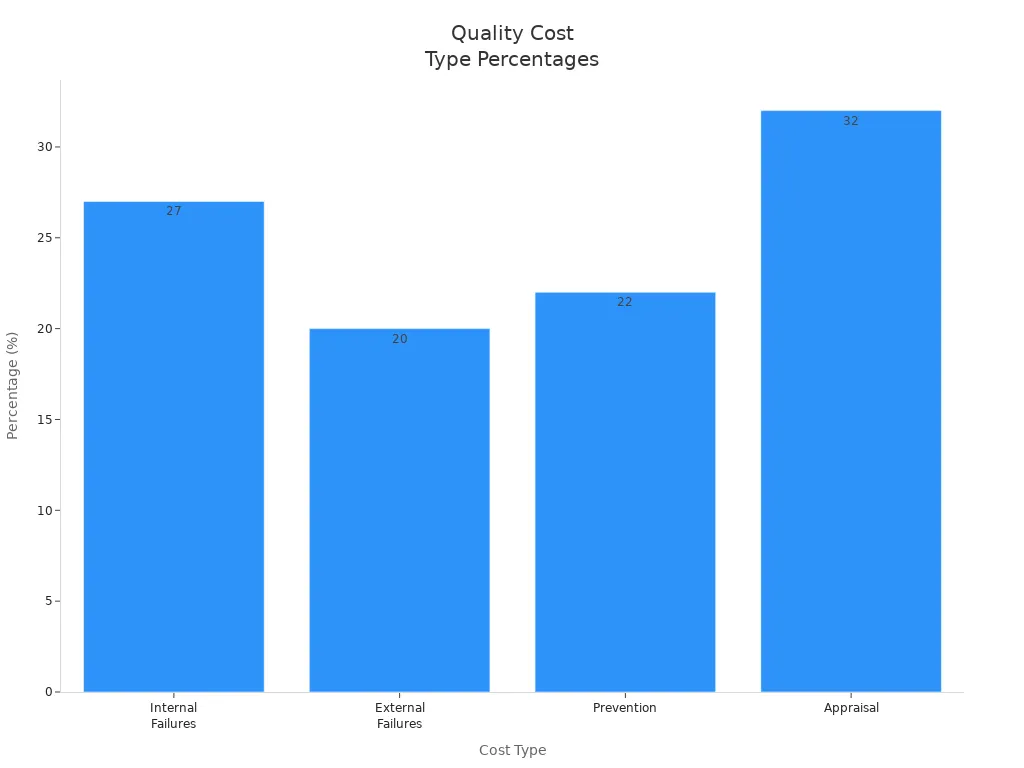

External failure costs show up when customers find problems after they get your product. These costs include returns, recalls, repairs, and losing sales. They can also hurt your company’s name and make customers trust you less.

| Cost Type | Percentage |

|---|---|

| Internal Failures | 27% |

| External Failures | 20% |

| Prevention | 22% |

| Appraisal | 32% |

You should try to keep external failure costs low. When you focus on quality at every step, you protect your company’s name and keep your customers happy.

Benefits of Cost of Quality Analysis

When you look at the cost of quality, you see how your company can get better. You find out where your money goes. You learn how each part of your work changes your results. Cost of quality analysis helps every part of your business. You find ways to fix problems, waste less, and make better things. You also help your company follow rules and earn trust from customers. If you keep trying to improve, your company can do well for a long time.

Identifying Improvement Areas

Cost of quality analysis helps you see where your company needs to improve. It shows which activities cost the most and where you lose money. You can focus on these spots to make things better. When you break down your quality costs, you see which steps need more help. This lets you make smart choices and use your money well.

- Cost of quality analysis helps you see how quality affects your money. You use this to make better choices.

- You can find areas with high quality costs. This helps you put money where it stops problems and makes things better.

- When you sort your quality costs, you find places where you can save. This means better products and happier customers.

When you know where your biggest costs are, you can plan ways to improve that really work. You do not have to guess. You use facts to help you decide.

Reducing Waste

You want to waste less and save money. Cost of quality analysis shows you where waste happens. You can then fix these problems. Many companies have saved a lot by doing this.

- A big car parts company cut warranty costs by 80% using Six Sigma. They fixed a $12 million problem and got a 400% return in one year.

- In factories, poor quality can cost over $280,000 because of waste.

- If you spend money to stop problems, you can get back two times or more. This proves that quality work pays off.

You can use these facts to help your own plans to improve. When you waste less, you spend less and earn more. You also help the planet by using fewer things.

Tip: Every dollar you save by wasting less can help you make your business better.

Enhancing Product Quality

You want your products to be the best. Making products better starts with knowing your costs. When you check the cost of quality, you see what you gain from each fix. You can measure how better supplier checks, early problem finding, and faster releases help you. These steps give you better products and lower costs.

Looking at the cost of quality shows you how your quality work saves money. You can lose fewer batches by checking suppliers better. You can pay less for labor by catching mistakes early. You can release products faster by making your work smoother. All these things help you reach your money goals and keep customers happy.

When you work on making products better, your brand gets stronger. Customers notice when your products last and work well. This means they come back and buy more.

Supporting Compliance

You have to follow rules in your field. Cost of quality analysis helps you stay on track. You can see where you spend money on following rules and if you need to do more. This keeps your company safe from fines and keeps your good name.

When you keep improving, you make sure your work meets all rules. You can show proof if someone asks. This helps customers and rule-makers trust you.

Note: Following rules is not just about staying out of trouble. It also shows you care about quality and always getting better.

By using cost of quality analysis, you get many good things. You find places to improve, waste less, make better products, and follow rules. These steps help you make smart choices, spend less, and keep customers coming back. The benefits of cost of quality analysis give you a plan for always getting better and doing well for a long time.

How to Measure Cost of Quality

Setting Up a Framework

You need a simple plan to measure cost of quality. First, write down all activities that affect quality in your company. Put these activities into four groups: prevention, appraisal, internal failure, and external failure costs. Give each activity a cost. This shows where your money goes and how each part affects quality. You can use a checklist or a spreadsheet to keep track. A good plan helps you see the whole cost of quality and make better choices.

Tip: Check your plan often. Change it when your work changes or when you find new ways to make quality better.

Data Collection Tools

You need good data to measure cost of quality. Use tools that help you track costs and problems with quality. Many companies use software, spreadsheets, and automatic tracking systems. Good data management makes sure your data is complete and correct. You should use best ways to keep your data clean and true.

| Best Practice | Description |

|---|---|

| Data Validation | Checking data helps you fix mistakes and makes data more accurate. |

| Data Cleansing | Cleaning data often helps you find and fix problems in records. |

| Data Governance | Good rules give order and make sure everyone uses data the same way. |

| Data Quality Tools | Using tools helps you find, fix, and stop mistakes in big sets of data. |

- Good data management helps you trust your numbers.

- Clean data shows the real cost of quality and helps you find ways to make things better.

Analyzing Results

After you get your data, you need to look at the results. Look for patterns in your cost of quality numbers. Find places where costs are high or where problems happen a lot. Use charts and graphs to make your data easy to see. Good data stories help you turn numbers into actions. When you fix data problems, you get better reports and learn more. This helps you make smart choices and improve quality.

- Companies lose money when data is bad. Bad data can slow down choices and stop new ideas.

- Good analysis helps you find problems, lower costs, and make quality better.

- Use what you learn to set new goals and watch your progress.

Note: Looking at your cost of quality data often helps you stay ahead and keep your company strong.

Overcoming Challenges

Data Collection Issues

Collecting cost of quality data can be hard. You want your data to be right and easy to use. Sometimes, reports have mistakes. These mistakes can make you lose money. If your data is missing parts, you may not see all problems. Bad data governance makes records messy and unsafe. It can be tough to link cost of quality data to other systems.

- Wrong data can confuse people.

- Missing data hides real costs.

- Bad data rules make numbers hard to trust.

- Problems with linking data slow down work.

If you do not fix these issues, you could get fined. Your team may waste time fixing data instead of making things better. You want to stop problems that hurt your business.

Tip: Check your data often. Use easy tools to keep cost of quality records clean and correct.

Team Buy-In

Your team needs to support cost of quality measurement. Some people may not like new systems. You can help by sharing real stories. Show how saving money helps everyone and keeps jobs safe. When you show quick wins, people start to trust you. Ask your team for ideas and reward good ones. This helps everyone feel included.

- Talk about the benefits in simple ways.

- Explain how saving money helps in the long run.

- Show small wins to get people excited.

- Ask for ideas and reward new ones.

When your team feels included, they work harder to improve quality. You build a place where everyone cares about cost and quality.

Integration with Business Processes

You want cost of quality measurement to fit into daily work. Start with strong support from leaders. Clear goals and resources help you do well. Let employees make choices about quality. Use good data to guide your actions. When you focus on quality everywhere, your company gets stronger.

- Leaders help set clear goals.

- Employees working together makes better teams.

- Using data helps you find ways to improve.

- A quality culture makes everyone want to do well.

You can use cost of quality data to spot problems and make smart changes. When you connect cost of quality measurement with your work, you save money and get better results.

Note: Building a quality culture takes time. Keep sharing progress and celebrate every win.

Measuring the cost of quality helps your business get better everywhere. When you keep track of cost of quality, you find weak spots and make smarter choices. Companies that care about quality from the start, use process control, and fix problems quickly have less waste and work better. You also make customers trust you more by keeping high quality and lowering the cost of poor quality.

Try these steps to measure cost of quality:

- Make clear goals for quality.

- Write down the main processes.

- Give people jobs for quality checks.

- Plan to check things often.

- Keep records that are easy to find.

- Always look for ways to do better.

When you track cost of quality, you get a real benefit. You save money, keep customers happy, and help your business grow.

FAQ

What is the cost of quality control?

You find the cost of quality control by adding up money spent on prevention, checking, fixing mistakes, and handling customer complaints. This total tells you how much you pay to keep products or services good.

Why should you track quality costs?

Tracking quality costs helps you find waste and fix problems early. You save money and make better products. Your company gets stronger and keeps customers happy.

How often should you review quality control costs?

You should check quality control costs every month or every quarter. Regular checks help you see patterns and make quick changes.

Can small businesses benefit from cost of quality analysis?

Yes! Small businesses can use cost of quality analysis to save money and make products better. Even simple tracking helps you spot problems and make smart choices.

What tools help you measure quality costs?

You can use spreadsheets, quality management software, or checklists. These tools help you organize data, track spending, and find ways to improve.